Meet the farmer...

On Raymond Orr’s farm in County Tyrone, Northern Ireland, his first job of the morning is letting out a total of 29,000 chickens keen to get on with their day. The birds are free range, which means during daylight hours they can go in and out of sheds as they please, with most choosing to spend their time outside in the grassy paddocks.

‘They get to behave as they naturally would, pecking around in the grass,’ says Raymond. ‘They’ve got perches and straw bales outside too.’ Light, airy houses give the birds protection at night.

Raymond has supplied chicken for Waitrose & Partners for 15 years. In addition to the standards for free range birds, a detailed set also apply to Waitrose Duchy Organic chickens and those reared for the essential Waitrose range. These birds live indoors but have 20% more room than the industry standard, lots of natural daylight, perches to fly up to and straw bales to peck at.

Waitrose & Partners has held a Compassion in World Farming Good Chicken Award since its inception in 2010.

We've signed the European Better Chicken Commitment

Waitrose & Partners is one of the only UK retailers to have signed the 2026 European Chicken Commitment, pledging to play a leading role in improving the welfare of our farmed chickens.

Under this Commitment, we pledge that all fresh and frozen chicken, and all chicken meat ingredients will meet the requirements by 2026. We already comply with the vast majority requirements of the pledge, including stocking density, for all our fresh and frozen own label chicken.

Working alongside Compassion in World Farming and our long term poultry supplier and research partner Moy Park, we are pleased to work towards this 2026 goal and help lead research into new breed requirements that will improve the welfare of all farmed chickens. Read more about our pledge on our animal welfare page.

Free range British chicken

These birds, which are reared for longer, have access to pasture daily, where they can run, dustbathe and forage. At night, the birds return to houses for protection. Chickens are descended from jungle fowl that naturally live in the undergrowth so we provide cover and shelters to make them feel protected and secure. To learn more see the video on this page.

Waitrose & Partners No.1 free range corn-fed British chicken

This richly flavoured meat has a characteristically golden colour to the flesh, which comes from its maize based diet. This corn-fed chicken is for our very best No.1 Waitrose & Partners range. The birds are raised on British family farms. They roam in grassy paddocks with trees and hedgerows and express their natural foraging behaviour.

Waitrose Duchy Organic free range British chicken

Reared from a slower-growing breed and farmed to strict organic standards, they are free to roam in organic pastures (returning to houses at night for protection) and fed an organically grown diet. They typically have access to larger outdoor ranges than free range chickens.The organic farms are audited by the Organic Farmers and Growers certification body.

essential Waitrose & Partners British chicken

essential Waitrose & Partners chicken is produced by farmers who have worked exclusively for us for several years. They understand the importance of quality standards in producing succulent chicken. They also feel as passionately as we do about standards of animal welfare.

Birds are reared in purpose-built houses with large windows on each side to allow natural light in. They have straw bales to play with to keep them fit and active, which allows them to behave naturally and are fed a diet enriched with maize which gives excellent eating quality.

These standards go beyond the RSPCA's recommendations for stocking density and has the support of animal campaign group Compassion In World Farming (CIWF).

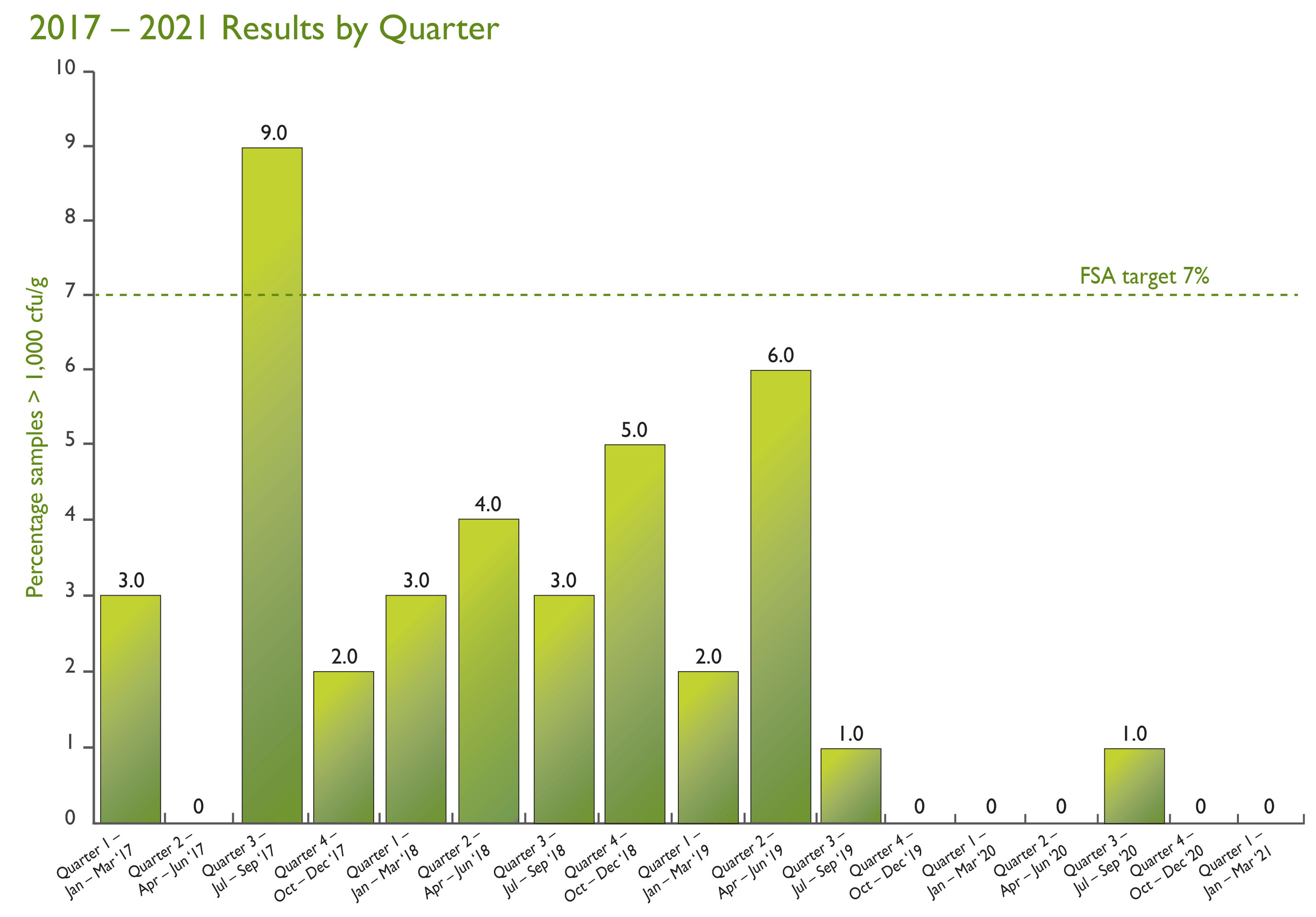

Campylobacter surveillance results October – March 2021

The results of our campylobacter survey (see graph below) for the first quarter of 2021, shows that Waitrose & Partners had 0% of chickens testing positive for levels of campylobacter >1000 cfu/g (colony forming units) over the period.

'The key to our good results continue to be the incredible hard work of our farmers and suppliers combined with our own rigorous data gathering and analysis, surveying chicken both at the factory and on supermarket shelves,' a Waitrose & Partners spokesperson said.

'We are again delighted that our results are 0% - the FSA target is 7% or fewer samples testing >1000cfu/g.

'Our testing regime is rigorous and because we know that the prevalence of campylobacter is reduced over a product's shelf life, we have ensured our sampling is random and have adhered throughout the survey to the FSA testing protocol.

'These results demonstrate the robustness of our testing procedures and we are confident our approach to tackling campylobacter is consistently effective.'

Waitrose takes its commitment to reducing campylobacter very seriously and is a long-term supporter of the FSA's efforts to eradicate the organism from the poultry supply chain.

We only source our chicken from carefully selected UK family farms that we know and trust and we continue to work hard to ensure that the poultry they supply are raised in the very best welfare conditions at low stocking densities.

In partnership with our processor, we have developed a cutting edge end to end process to reduce campylobacter in our supply chain.

Waitrose & Partners ‘end to end’ campylobacter action plan

On farm: Our work on farm is focused on those areas that have had the most significant and consistent impact on campylobacter levels. Specifically:

Enhanced biosecurity: We have installed an industry-leading ‘double barrier’ enhanced bio-secure system on all of our poultry farms. Our strategy has been holistic in terms of biosecurity before, during and after the rearing cycle to minimise the risk of campylobacter colonisation of our birds.

In addition, we have trained all our farmers and catching teams in biosecurity measures and installed communication boards in all our poultry houses, further enforcing communication and industry-leading bio-security practices. All farms are audited every crop cycle by a central audit team to monitor compliance. We regularly monitor compliance in this area.

Days between ‘thin’ and ‘clear’: Through a non-invasive method of on farm testing we have found that increasing the number of days between ‘thin’ (when a proportion of birds are removed from the flock) and ‘clear’ (when the whole flock is taken from the poultry house for processing) increases the risk of campylobacter colonisation at higher levels.

Farm and shed infrastructure: Our investigations have shown that there are lower levels of campylobacter in chickens that live in fan ventilated, steel-framed houses that are less than 15 years old. The vast majority of our farms have broiler houses that are less than 10 years old. Further to this, all our new supply farms comply with our ‘farms of the future’ standards. Our ‘farm of the future’ project involves work around ensuring we source chicken from the most forward thinking suppliers in terms of investment in new, cleaner buildings, drinkers, heating systems, farm access management, data capture, litter management and bird welfare standards.

Training: Our farmers and their teams receive regular training to ensure they operate to the very highest hygiene standards. Hygiene best-practice information boards have been put in place at all our supplying farms.

Alternative heating sources: There is some evidence to suggest that drier heating systems such as indirect heating sources / hot water heating systems can reduce the prevalence of campylobacter. However, research in his area is still at an early stage and we are using global benchmarking and on-going data analysis to determine the impact this could have. Biomass and indirect heating systems have been installed across our supplying farms.

Benchmarking learning: We are working with researchers from the UK and internationally to share best practice in areas that we believe will bring significant benefit including improved management of water drinkers on farm and improved management of the environment in our chicken houses.

At the processor: The way birds are processed has an impact on levels of campylobacter. We have focused on the following areas because we believe they offer the most significant benefit:

Optimising procedures: Our supply facilities operate to the highest hygiene standards and have optimised procedures including lairage, module crate washing and inside/outside washer efficacy.

Neck flap removal:

We remove the neck flap from processed birds as our research suggests that this is an area where campylobacter may become concentrated.

Packing line segregation:

Process flow changes have been implemented in the packing areas of all our supply factories to segregate unsealed and sealed packs. This minimises the possibility of campylobacter being transferred to the outside of packs.

Packaging: We have a range of oven ready birds sold in a ‘ready to roast bag’ which are ideal for customers who would rather not handle raw chicken – we were pioneers of this approach.

Work with customers: We know that the way raw chicken is handled and cooked at home is key to food safety and that is why we have worked hard to inform customers of the importance of proper awareness in the kitchen:

Communication: We have communicated the safe handling of chicken message in-store, on pack and through our marketing channels including Waitrose Weekend and Waitrose Food publications, on our website and social media. We will continue to highlight the best ways of handling raw chicken.

Work with industry: We play an active role in industry-wide research on campylobacter:

In-house workshops: We run our own in-house campylobacter workshops with Professor Chris Elliot - a leading expert on food safety – and representatives from the FSA.

Engagement: Members of our in house teams sit on the FSA’s on campylobacter Together Board (ACT)

We believe that our extensive action plan has driven our success in driving down campylobacter levels in our chicken supply chain.